Demystifying the Process of Photolithography in Chip Manufacturing

If you’ve ever used a computer or smartphone, you’ve likely benefitted from the incredible advancements in chip manufacturing. The production of these tiny but powerful chips involves a complex and precise process known as photolithography. But what exactly is photolithography and how does it contribute to the creation of the processors and memory chips that power our devices? In this article, we will take a closer look at the process of photolithography in chip manufacturing, demystifying this crucial step in the production of modern technology.

The Basics of Chip Manufacturing

Before diving into the intricacies of photolithography, it’s important to understand the basics of chip manufacturing. In simple terms, chip manufacturing involves using specialized machines to etch microscopic circuits onto a silicon wafer, which is then divided into individual chips.

The process begins with a clean silicon wafer that is then coated with a light-sensitive material called photoresist. A mask, containing a pattern of the desired circuit, is then placed over the wafer. The wafer is then exposed to a specific wavelength of light which causes the photoresist to become either more or less soluble depending on the type of resist used.

Demystifying Photolithography

Step 1: Exposure

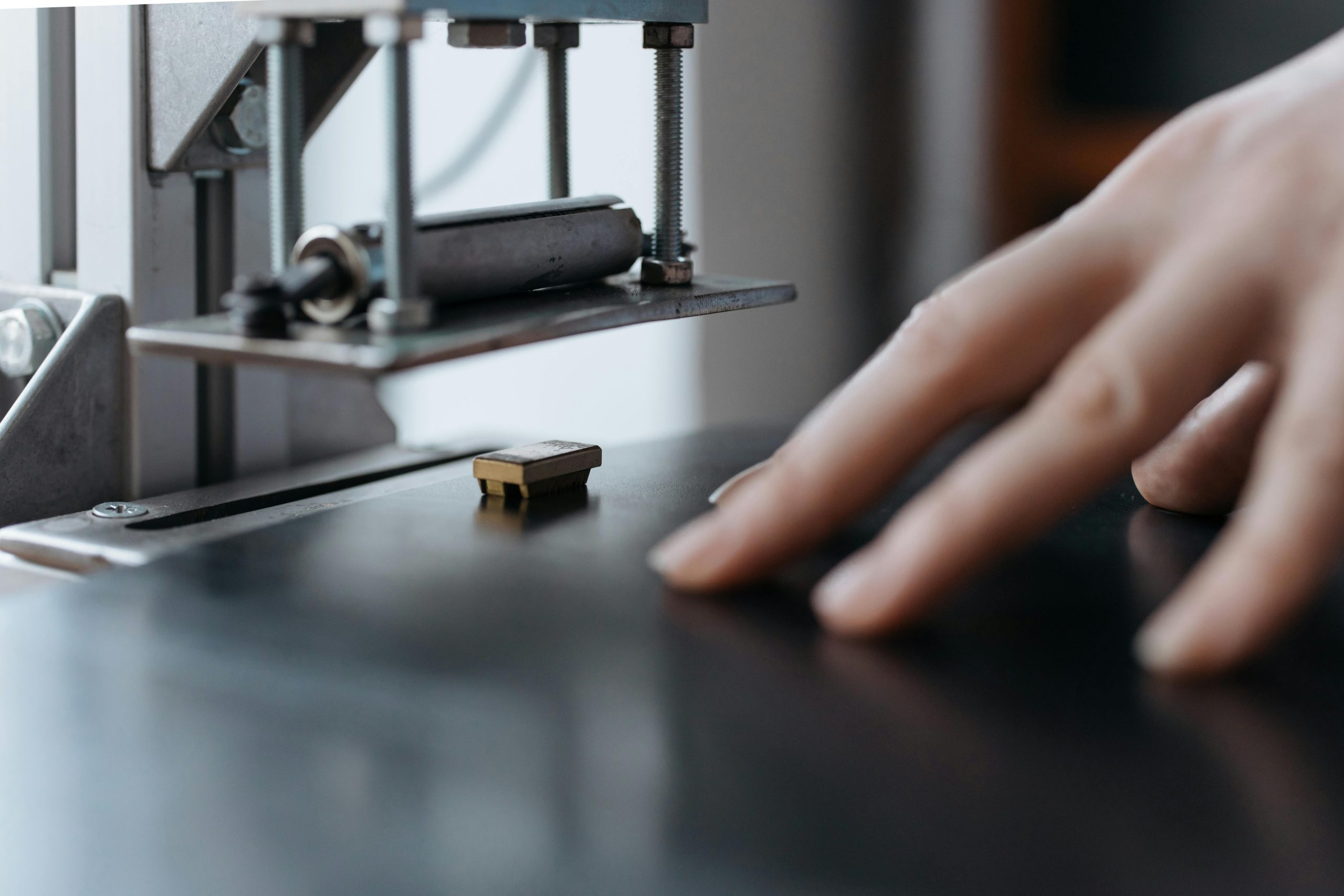

The first step in the photolithography process involves exposing the coated wafer to a specific wavelength of light. This is usually done using a specialized machine called a photolithography stepper. This machine uses lenses and mirrors to project the desired pattern onto the photoresist-coated wafer.

Step 2: Developing

After exposure, the wafer is then placed in a developer solution that removes the photoresist that was exposed to light. This creates a pattern of the desired circuit on the wafer. The areas where the photoresist has been removed will later be etched away, leaving behind a pattern of exposed silicon.

Step 3: Etching

The next step is etching, where the exposed silicon is removed using a chemical process. This allows for the creation of the intricate circuit structures that make up a chip. The type of etching used depends on the type of circuits being created and can be either wet or dry etching.

Step 4: Doping and Oxidation

Once the circuit structures have been created, the wafer is then subjected to two additional processes – doping and oxidation. Doping involves introducing impurities into the silicon in order to alter its electrical properties. This creates a p-n junction, an essential part of any transistor. Oxidation, on the other hand, involves exposing the wafer to oxygen which creates a thin layer of silicon oxide on the surface. This layer provides insulation and protects the circuits from contamination.

The Importance of Precision and Control in Photolithography

As you can see, photolithography is a crucial step in the production of chips. It allows for the creation of intricate and precise circuit patterns, which are essential for the proper functioning of a chip. This process requires extreme precision and control, as even the slightest error can lead to defects in the finished chip.

Modern chip manufacturing facilities use highly specialized equipment and advanced technologies to ensure the accuracy and precision of the photolithography process. In addition, extensive testing and quality control measures are in place to catch any errors and defects before the chips are released to the market.

The Future of Photolithography in Chip Manufacturing

The demand for smaller, faster, and more energy-efficient chips continues to drive advancements in photolithography. As a result, chip manufacturers are constantly pushing the limits of this process, developing new techniques and technologies to create more complex and powerful chips.

One such advancement is the use of extreme ultraviolet (EUV) lithography, which uses shorter wavelengths of light to create even smaller features on the wafer. This technology is still in its early stages but has the potential to greatly increase the efficiency and precision of chip manufacturing.

In Conclusion

As we’ve seen, photolithography plays a crucial role in the creation of the technology we use every day. This highly complex and precise process allows for the production of chips that are smaller, faster, and more powerful than ever before. With continued advancements and innovations in photolithography, the future of chip manufacturing is sure to be an exciting one.